Reducing Emissions

Minnesota Power continually monitors how each of our generating units fit within our long-term energy strategy to balance environmental impact, reliability and cost.

In December 2015, we completed a major environmental improvement project at Boswell Energy Center in Cohasset, Minn. Mercury and sulfur dioxide emissions were reduced by more than 90 percent from Boswell Unit 4, our largest generator and the workhorse of Minnesota Power’s generation fleet. In addition, 99.8 percent of particulates are being captured. The $240 million project took three years to complete.

Since 2005, we’ve invested more than $600 million at our coal-fired power plants to reduce emissions and improve efficiency. Much of this investment applied to Boswell Unit 4 and Boswell Unit 3, the company’s second-largest generator. Technology upgrades at Boswell, the idling of Taconite Harbor Energy Center and the conversion of Laskin Energy Center to natural gas generation have produced a 70 percent reduction of overall air emissions—including mercury, nitrogen oxide, sulfur dioxide and particulates—across the Minnesota Power generation fleet.

The technology solutions that Minnesota Power uses vary by plant to get the most reduction in emissions for the least cost to customers and to comply with federal and state regulations. Here are some highlights of what we’ve accomplished so far:

- Boswell Energy Center Unit 4 has been removing more than 90 percent of its mercury air emissions since December 2015 when a massive emissions control project was completed.

- Boswell Energy Center Unit 3 has been removing more than 90 percent of its mercury air emissions since 2009 when a similar emissions control project was completed.

- The two smallest units at Boswell are removing mercury at rates ranging from 60–80 percent and will be retired in 2018. Taconite Harbor Energy Center has been idled and will be restarted only to meet periods of high demand.

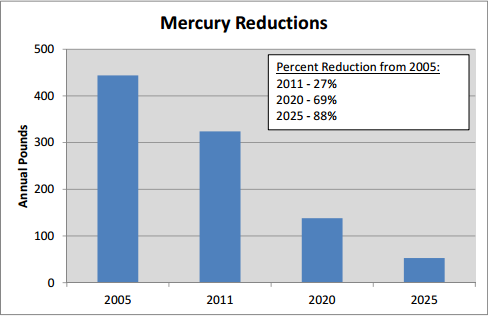

- Mercury air emissions across the generation fleet have been reduced by 60 percent since 2005.

- Minnesota Power’s overall air emissions, including mercury, nitrogen oxide, sulfur dioxide and particulates, have dropped about 70 percent since 2005.

- Mercury water emissions at Boswell have been reduced by more than 50 percent since 2001. Mercury water emissions have been nearly eliminated at Laskin.

- Minnesota Power is optimizing the use of biomass (wood waste) and reducing dependence on coal at the Hibbard Renewable and Rapids Energy Centers. Mercury concentrations in biomass are lower than in coal.

Mercury Reductions Achieved and Projected with Preferred Plan